Heat Recovery

Reduced Energy Costings – Energy usage accounts for the majority of lifetime ownership of a compressor, heat recovery will significantly reduce this .

Reduced Carbon Footprint – Heat recovery lowers the carbon footprint of a company and benefits the environment.

Low Capital Investment – A relatively small outlay can be quickly recovered by using the correct heat recovery method to suit you requirements.

A rotary screw compressor converts 100 % of the drawn electrical energy into heat. Up to 96 % of this energy can be recovered and put to good use elsewhere in your factory, with excellent payback results.

So where does the reusable energy in compressed air come from?

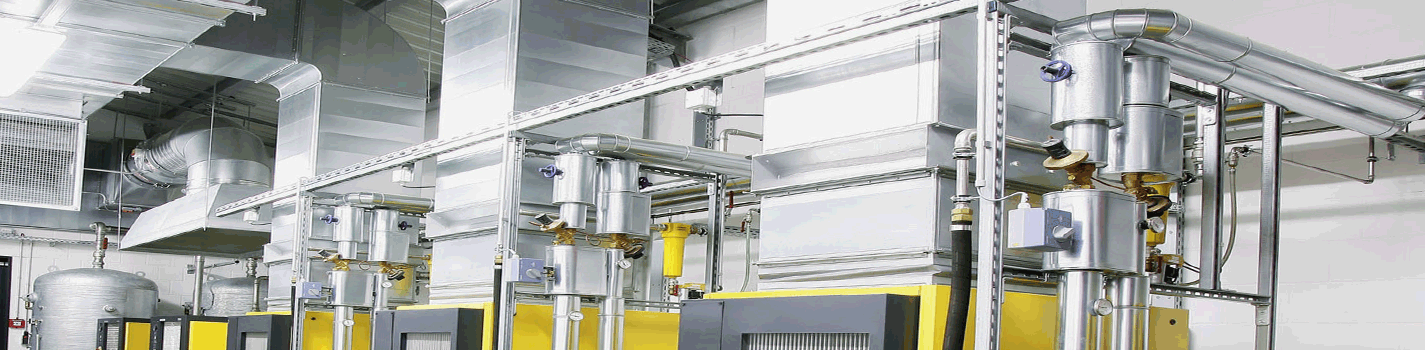

Warm Air Recovery – Because of the enclosed, compact construction of a screw compressor a simple ducting system can be used to transfer the warm cooling air to heat warehouses, workshops and adjacent facilities. This is the simplest and most cost effective way of reusing the hot air generated from the air compressor with typical paybacks of six months.

Heat Exchanger Systems –The HPC/ Kaeser range of compressors distributed by Marshall Brewson offer the option of supplying new compressors with energy saving heat exchanger/recovery system that can be easily integrated in any conventional water heating application. The water is heated through a heat exchanger by the oil from the fluid cooler. These heat exchangers can be supplied on a factory order, or in kit form and be retro fitted to most existing HPC compressors with typical payback of twelve months.

Contact our team for advice on how we can help reduce you carbon footprint.

The Benefits of Heat Recovery: