Ancillary Components

The range of ancillary products offered by Marshall Brewson are used to provide the perfect solution to your compressed air requirements, automotive, industrial, food industry, dental air, medical, breathing air or whatever ever industry or application. Marshall Brewson can offer a complete turnkey system package or point of use treatment to suit your requirements.

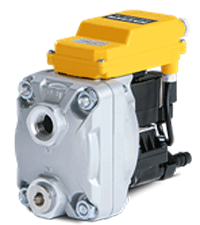

Inline filtration, refrigerant dryers, air storage receivers, oil/water separators, desiccant dryers, electronic condensate drains, pipework & energy efficient compressor controllers enable Marshall Brewson to offer a perfect solution to your compressed air requirements.

Marshall Brewson can supply compressed air to all ISO8573-1:2010 standards even class zero.

Why treat compressed air?

Even with an oil free compressor the compressed air needs to be treated, the atmospheric air drawn into a compressor is a mixture of Gases, Atmospheric dirt, Micro-organisms, oil vapours, Contaminants & water vapour. As the temperature increases in the compression process the air’s ability to carry moisture increases. When the air is cooled the excess moisture that is no longer carried is called condensate. This condensate & contaminated air need to be treated to prevent any problems downstream of the compressor house.

ISO8573-1:2010

ISO8573 is the group of international standards relating to the quality of compressed air. The standard has nine separate parts, part 1 specifies the quality requirements of the compressed air. Parts 2-9 specify the testing methods. The ISO8573-1 give 3 separate numbers for the air quality,

1.x.x The 1st number refers to the purity class of particulates

x.1.x The 2nd number refers to the purity class of water

x.x.1 The 3rd number refers to the purity class of oil

The lower the number the higher quality of compressed air.

Class 0 compressed air Class o does not mean zero contamination, class o requires the user & the supplier to agree contamination levels as part of a written specification. A compressor claiming to deliver class o will still need ancillary purification equipment in both the compressor room & at point of use for class 0 to be maintained.

For more information regarding ISO8573-1:2010

For more information regarding food quality compressed air