Air Demand Analysis

With compressed air often referred to as the 4th utility it is essential to not just consider the initial capital cost of an air compressor but to look at the efficiency, the correct sizing, and running costs of your potential purchase or even your existing compressor set up.

Compressed air can be the biggest user of energy in many companies but With accurate evaluation and monitoring of the demand on a compressed air system Marshall Brewson can help your company reduce it\’s carbon footprint, avoid downtime and loss of production, and save you money.

Compressors are at their most efficient at 100% full load, when producing compressed air constantly. A compressor running off-load (running but not producing air) still requires power, but at a much reduced level. As eliminating off-load running altogether is unlikely to be possible, off-load running efficiencies are important when considering running costs.

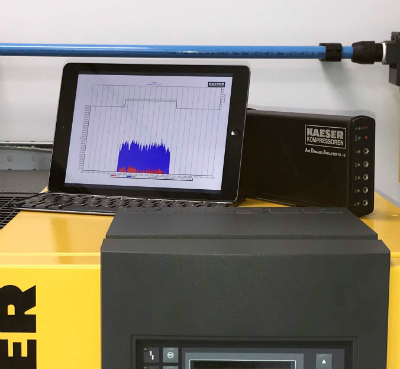

Data Logging – An electronic data logger/air demand analyser (ADA) can be installed to monitor and record the operating status of any existing compressor installation. The ADA can be installed quickly, without disruption, and will collect data at one-second intervals, 24 hours a day for 250 hours. The information logged is then downloaded to a PC and processed to produce an air demand analysis for the compressed air system. Discussing, and carefully considering all the requirements will provide a practical solution to suit the individual application.

Power Meters –Marshall Brewson use a power meter in conjunction with the ADA, this power meter monitors the voltage and current of any compressor to give a true \’off the wall\’ power usage of the compressor being analysed.

With the use of power meters and an ADA the Marshall Brewson team of experienced compressor system designers can provide a practical, cost effective, and carbon footprint reducing solution to suit any individual application.

ISO11011 – The British Compressed Air Society (BCAS) and the ISO Technical Committee have defined a new standard for compressed

air system assessment, called ISO11011. Its main purpose is to encourage businesses to assess their compressed air systems via companies that carry out energy audits in line with the new ISO guidelines – and to subsequently take the recommended actions to reduce their energy use.

For more information contact our sales team

The benefits of Air Demand Analysis:

Reduced Energy Costings – Energy usage accounts for the majority of lifetime ownership of a compressor, heat recovery will significantly reduce this .

Reduced Carbon Footprint – Heat recovery lowers the carbon footprint of a company and benefits the environment.

Low Capital Investment – A relatively small outlay can be quickly recovered by using the correct heat recovery method to suit you requirements.