Marshal Brewson offer the HPC/Kaeser range of high efficiency coalescing compressed air filters for the removal of water and oil aerosols, solid particulates and micro-organisms, and dust filters for the removal of dry particulate and micro-organisms from industrial compressed air systems.

Failure to remove or reduce contamination will cause a number of problems within the compressed air system. This can include corrosion within compressed air storage vessels and the air distribution system, as well as blockage or damage to production equipment; which can result in product contamination and unhealthy working conditions.

The HPC Kaeser Secotec thermal mass dryer series are the ultimate in energy saving dryers, these dryers save energy because the refrigerant system is shut down during breaks, periods of low demand and downtime – the control system operates without preset run-on periods. The integrated thermal mass ensures that the system is ready for operation at all times. SECOTEC dryers use flow-optimised piping so pressure losses are therefore kept to a minimum, which means that maximum system pressure can be significantly reduced. This leads to considerable savings, as each 1 bar reduction represents a 6 % decrease in power consumption and also means less air is lost through leakage. A further advantage of SECOTEC dryers is that they exceed the energy efficiency criteria required to be eligible for Enhanced Capital Allowances (ECA’s) so further savings can be made

Due to its storage and buffer capacity, the air receiver plays a key role within a compressed air installation: It provides capacity during periods of peak demand and is often used to separate condensate from the compressed air. Therefore, it is important for the receiver to be correctly sized for the specific system, to be resistant against corrosion and to have long inspection intervals. Air receivers from Marshall Brewson meet all of these requirements. Our standard range of air receivers are hot-dip galvanised internally and externally and supplied with full fittings kit. All sizes, pressures & materials of air receiver can be supplied to our clients’ specification, please contact the sales team for a quotation.

Users who dispose of condensate by simply pouring it down the drain risk heavy fines; this is because condensate accumulated during the production of compressed air is a highly noxious mixture. The HPC Owamat Oil/Water separators are used to separate the oil from water condensate generated by the compressed air system. This is achieved by allowing the oil to rise to the top of the Owamat chamber whilst the water is passed through a series of carbon filters thus allowing the processed water into the sewage system.

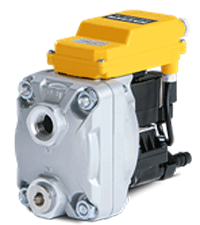

Condensate is an inevitable by-product of the process of compressing air and usually contains oil & dirt. If not reliably drained off at all collection points, it can cause operational disruption and severely damage the compressed air system through corrosion. Most conventional float drains are beset with problems; the timer drains are inefficient due to compressed air wastage if no condensate is formed. The HPC Ecodrain is an electronic drain with a built in sensor that only drains of condensate not valuable compressed air. The drain can handle dirt & oil without blocking.